-

RIGGING HARDWARE

- G100 RIGGING HARDWARE

- G80 RIGGING HARDWARE

- SHACKLES (INCL. G80 & S6)

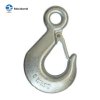

- HOOKS (G70, G43 ETC)

- LOAD BINDERS (INCL. G80)

- TURNBUCKLES

- BOLTS & NUTS, RINGS

- CHAIN SWIVELS & LINKS

- WIRE ROPE CLIPS

- WIRE ROPE THIMBLES

- WIRE ROPE FERRULES, TERMINALS & SOCKETS

- SNAP HOOKS, TRIGGER SNAPS & QUICK LINKS

- STAINLESS STEEL RIGGING HARDWARE

- STAINLESS STEEL MARINE HARDWARE

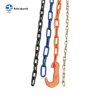

- STEEL CHAINS & SLINGS, TIRE CHAINS

- WIRE ROPES, SLINGS & LOOPS

-

CARGO CONTROL & RESTRAINT

- POLYESTER LIFTING SLINGS

- RATCHET STRAPS & PACKAGE KIT

- WINCH STRAPS & TOW STRAPS

- HARDWARE FOR CARGO CONTROL STRAPS

- FULL BODY SAFETY HARNESS

- BUNGEE CORDS

- CARGO BARS & JACK BARS

- SHORING BARS

- DECKING BEAMS

- CARGO PARTING WALL LOCKS / PLANKS

- CARGO CONTROL TRACKS / TIEDOWN RAILS

- WINCH BARS

- WHEEL PIN PULLER & OTHERS

- MATERIAL HANDLING & TOOLS

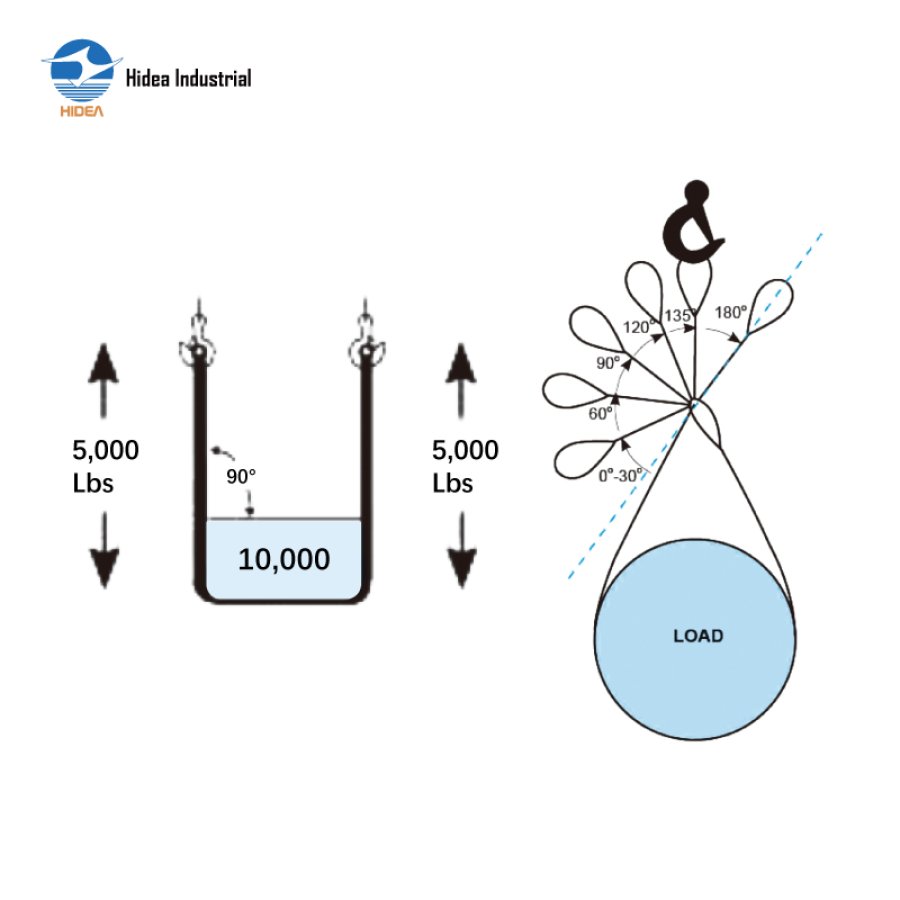

A more salient approach to determine sling adequacy is the calculation of INCREASED TENSION resulting from the Sling-to-Load Angle. This approach has the distinct advantage of enabling the sling user to determine the required sling strength requirement. The user must first determine the angle and multiply the load weight (per leg) by the tension factor for the specific angle, and the result is the INCREASED TENSION or actual loading on the sling leg(s).

1.Calculate the Sling to Load Angle.

2. Determine the corresponding Tension Factor

3.Multiply the load weight (per leg) by the Tension Factor to determine the increased tension on the sling leg(s).Use the same way above to calculate the application case actual loading for the choker hitch angle webbing sling with their reduction factors

QINGDAO HIDEA PARAMETER SHEET FOR

SLING-TO-LOAD ANGLE &CHOKER HITCH ANGLE

| TENSION FACTOR CHART | ||||||

| ANGLE"A" DEGREES | TENSION FACTOR | ANGLE"A" DEGREES | TENSION FACTOR | |||

| 90 | 1.000 | 55 | 1.221 | |||

| 85 | 1.004 | 50 | 1.305 | |||

| 80 | 1.015 | 45 | 1.414 | |||

| 75 | 1.035 | 40 | 1.555 | |||

| 70 | 1.064 | 35 | 1.742 | |||

| 65 | 1.104 | 30 | 2.000 | |||

| 60 | 1.155 | 25 | 2.364 | |||

| SUNG TENSION INCREASES AS THE SUNG-TO-LOAD ANGLE DECREASES AT 90°-SLING TENSION=5,000 PER LEG AT 60°-SLING TENSION=5,775 PER LEG AT 45°-SUING TENSION=7.070 PER LEG AT 30°-SLING TENSION=10,000 PER LEG | ||||||||||||

| SLING-TO-LOAD ANGLE (DEGREES) | 90° | 60° | 45° | 30° | ||||||||

| LOAD WEIGHTXTENSION FACTOR | 10,000Lbs ×1.000 | 10,000Lbs X1.155 | 10,000Lbs X1.414 | 10,000Lbs ×2.000 | ||||||||

| INCREASED SLING TENSION | 10,000 Lbs | 11,550 Lbs | 14,140 Lbs | 20,000 Lbs | ||||||||

| CHOKER HITCH ANGLE REDUCTION CHART | |

| Choker Hitch Angle (Degrees) | Reduction Factor |

| 120-180 | 1.00 |

| 105-120 | 0.82 |

| 90-105 | 0.71 |

| 60-90 | 0.58 |

| 0-60 | 050 |