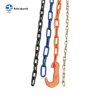

Wire rope fittings—shackles, turnbuckles, clips, thimbles, and swages—are essential for rigging, lifting, and securing heavy loads. But how do you know when to reuse them and when to replace them?Using damaged or worn wire rope fittings can lead to catastrophic failures, risking worker safety and costly downtime. On the other hand, replacing fittings too soon wastes money and resources.

Reuse or replace? This guide will make it simple.

1. Red Flags - Time to Break Up

A. Visible Damage Requiring Immediate Replacement

○ Cracks, bends, or elongation in shackles, hooks, or clips

○ Structural corrosion compromising integrity

○ Worn or distorted threads on load-bearing components

B. Excessive Wear Beyond Allowable Limits

○ Wire rope clips with deformed saddles

○ Thimbles with grooves exceeding 10% of rope diameter

○ Swaged fittings showing slippage

C. Overload Conditions

○ Exposure to loads beyond rated WLL

○ Subjected to sudden shock loads

2. Second Chances? Maybe...

A. Superficial Corrosion

○ Light surface rust that can be removed and treated

○ Exception: Pitting deeper than 10% of material thickness requires replacement

B. Minor Wear Within Tolerance

○ Slightly worn clips that can be properly re-tensioned

○ Shackle pins with minimal wear and no deformation

C. Properly Maintained Fittings

○ Regularly lubricated components

○ Stainless steel fittings in good condition

3. Industry Retirement Standards

| Standard | Replacement Criteria |

| ASME B30.26 | Cracks, bends, or >10% wear |

| OSHA 1926.251 | Mandatory if deformed/damaged |

| EN 13414-1 | Corrosion affecting integrity |

| ISO 4309 | After extreme load exposure |

4. Service Life Extension Practices

A. Inspection Protocol

○ Daily visual checks before use

○ Monthly measured inspections

B. Proper Handling

○ Store in dry, controlled environments

○ Avoid impact damage during handling

C. Material Selection

○ Stainless steel for corrosive environments

○ Galvanized steel for outdoor use

○ Alloy steel (G80/G100) for heavy loads

5. Risk vs. Cost Analysis

| Risk of Reuse | Benefit of Replacement |

| Equipment failure | Minimal replacement cost |

| Safety incidents | Uninterrupted operations |

| Regulatory non-compliance | Maintained certification |

Conclusion: Prudent Maintenance Approach

Wire rope fittings aren't "til death do us part" items. They require disciplined inspection and timely replacement. While minor wear may permit reuse, any critical damage demands immediate retirement.

Recommended Practices:

● Conduct pre-use inspections

● Adhere to manufacturer wear limits

● Replace at first signs of critical damage

● Implement regular staff training

When uncertain, replacement is the conservative and safe choice. Proper maintenance ensures both safety and operational efficiency.

|  |  |  |